Latest news

CamperBALANCE-Pro (CBP)

CBP is a self-developed electronic gyroscope (comparable to a digital spirit level) for motorhomes and vans. After a one-time, quick and vehicle-specific calibration, it indicates under which wheel a wedge with how many centimeters must be placed in order to stand perfectly in the water.

- No more spirit levels, apps and other aids and wedging by feel with great inaccuracy.

- No more pans that are crooked and food burns on one side of the pan

- No more shower water collecting in a corner of the bath.

- No more m&m's rolling off the dining table because you're not standing perfectly in the water.

- No more cell phone apps that display on the dining table behind the driver that you are standing at an angle but are not really visible to the driver behind the steering wheel when driving onto the wedges.

Priceless? Not at all, the CBP costs only 59,00 EUR plus domestic shipping costs for the first 10 units sold!

Gear for electrical step (like of Project2000/Reimo)

Stainless steel gear rod as spare part for steps of the Reimo Project2000 step and other models (type 10856 steps).

The original nylon gear rod of the Reimo Project 2000 step series, as well as all models of step type 10856, are equipped with a gear rod. This rod is inserted directly into the motor drive on one side and held on the opposite side with a pin. The actual drive pinion comes around this gear rod and can slide up and down on the gear rod. This drive pinion drives a twin pinion and one of the two large drive wheels for the step extension.

This gear rod is subject to high shear forces. Design errors and some points that must be observed during installation will sooner or later lead to breaking/tearing of the rod as it cannot withstand the shear forces.

After almost 7 months, we have managed to find a supplier who can produce this gear rod in stainless steel at an acceptable price (close to the original gear). We received the final prototypes and identified the model that fits perfectly and over which the drive pinion slides perfectly, just like on the original rod.

Link to item in shop.

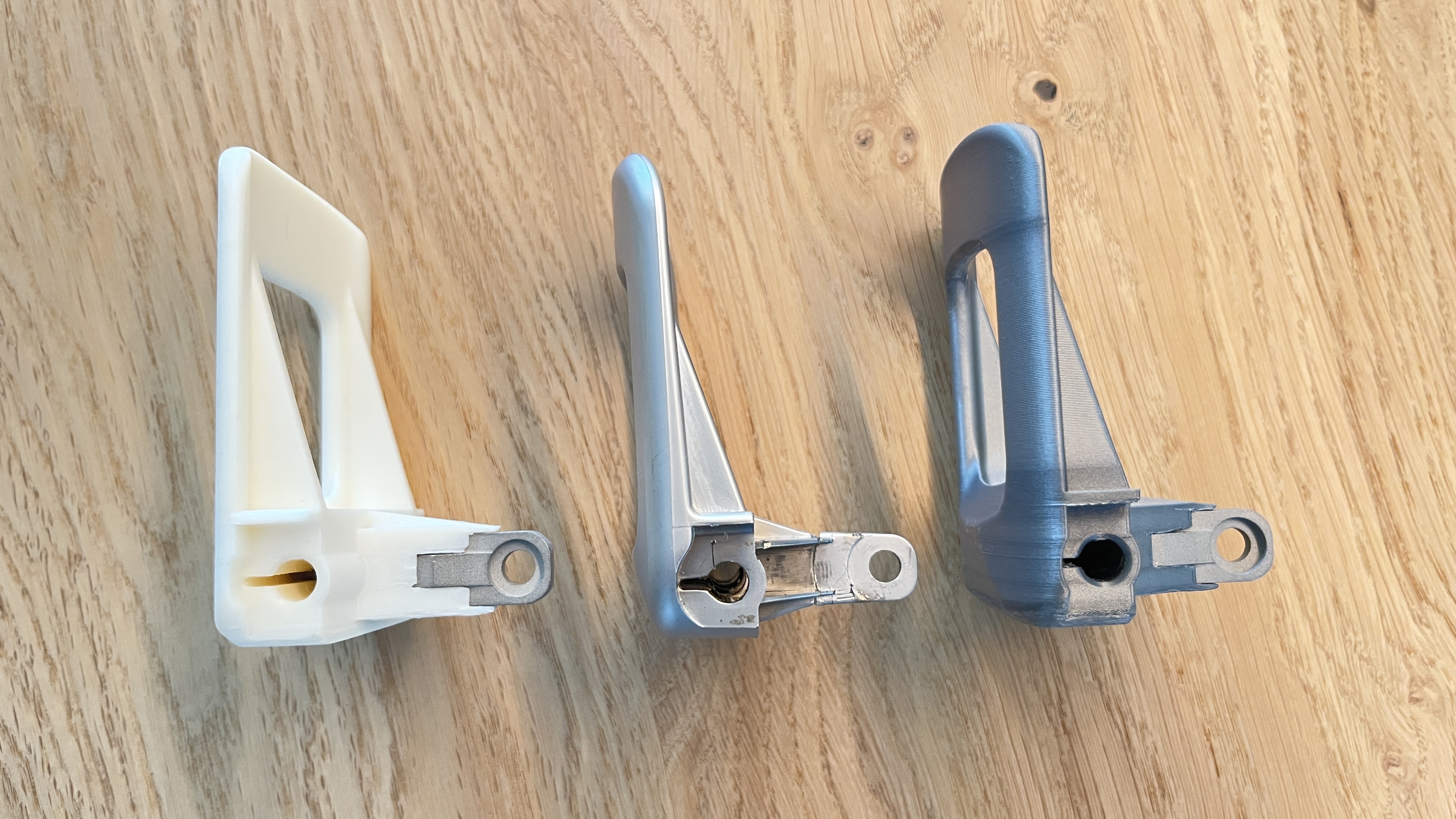

Replacement handle for body door and its evolution

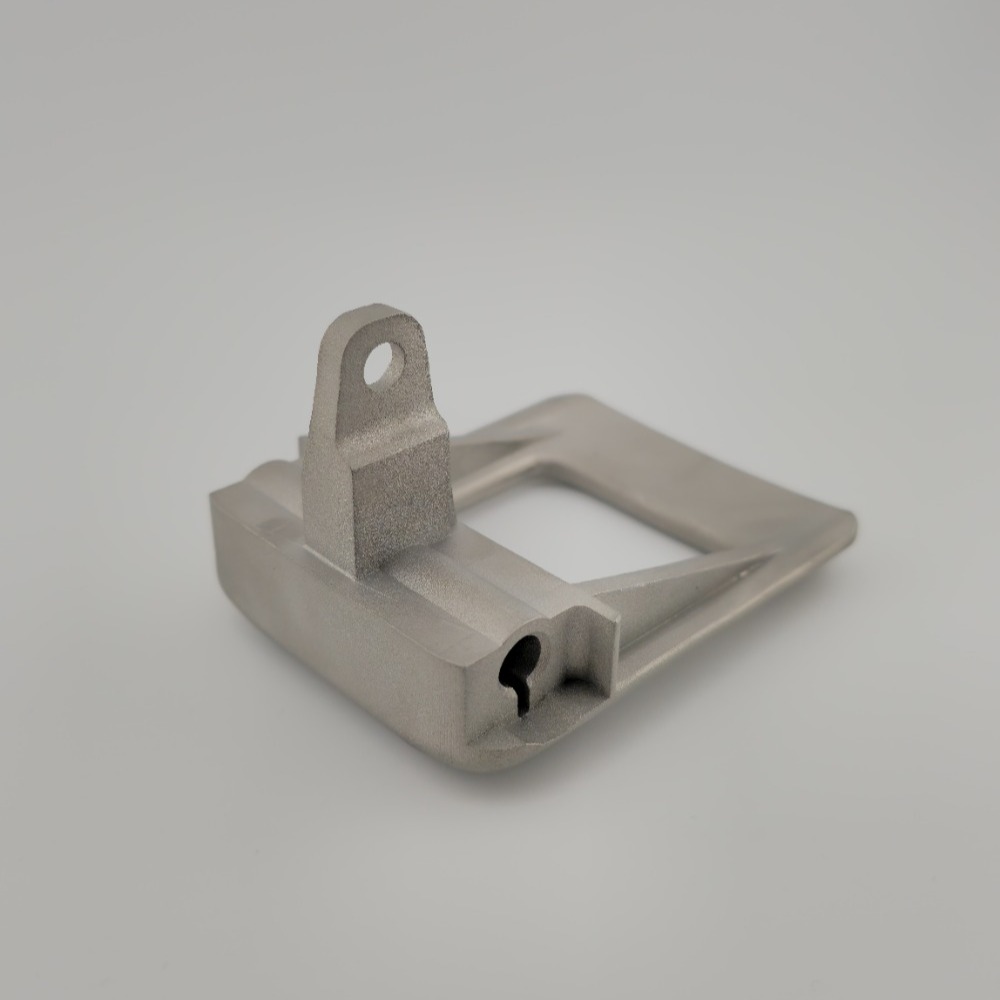

Replacement handle in various materials, including a version with stainless steel inlay.

This item was created in response to a request from a customer who asked for a quote for a replica of the door handle on his body door.

This item was created in response to a request from a customer who asked for a quote for a replica of the door handle on his body door.

The interior door handle on his motorhome—the handle needed to open the body door from the inside—had suddenly stopped working.

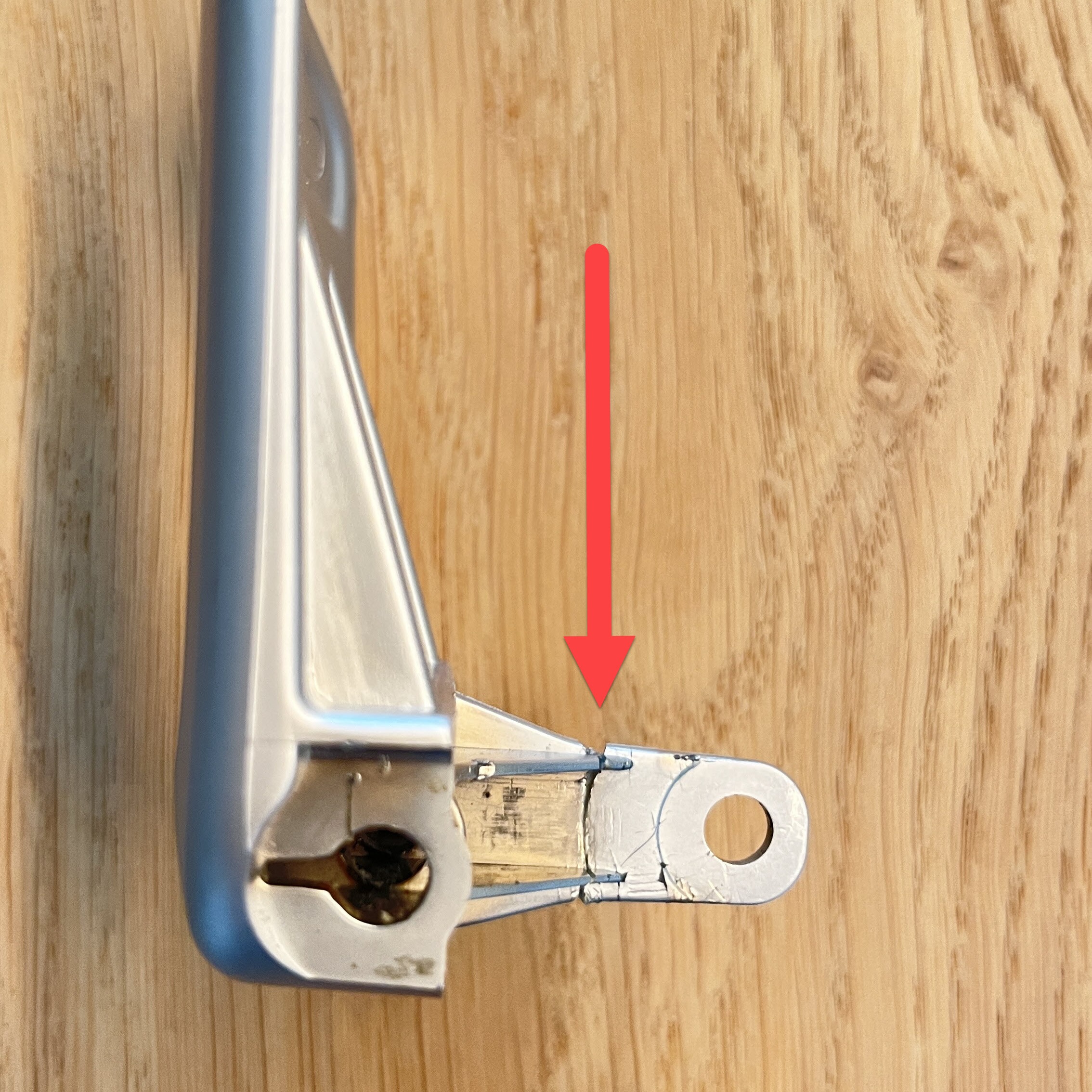

When the door trim was removed, it was immediately clear what had happened. The eyelet on the handle that activates the internal mechanism had broken.

The manufacturer of the handle had been insolvent for several months and was no longer operating on the market.

There was also no replacement or solution available from the motorhome suppliers. Although all suppliers regretted his situation, no one was able to help with a solution.

One of our posts on Facebook brought us to the customer's attention, and he asked for a quote for a replica of the handle. In order to check the feasibility and estimate the approximate costs (for a quantity of only one piece), the customer sent us his broken handle. After checking the feasibility and estimating the approximate CAD working time required, we were able to provide the customer with a quote within a price range that he found acceptable, and the order was placed.

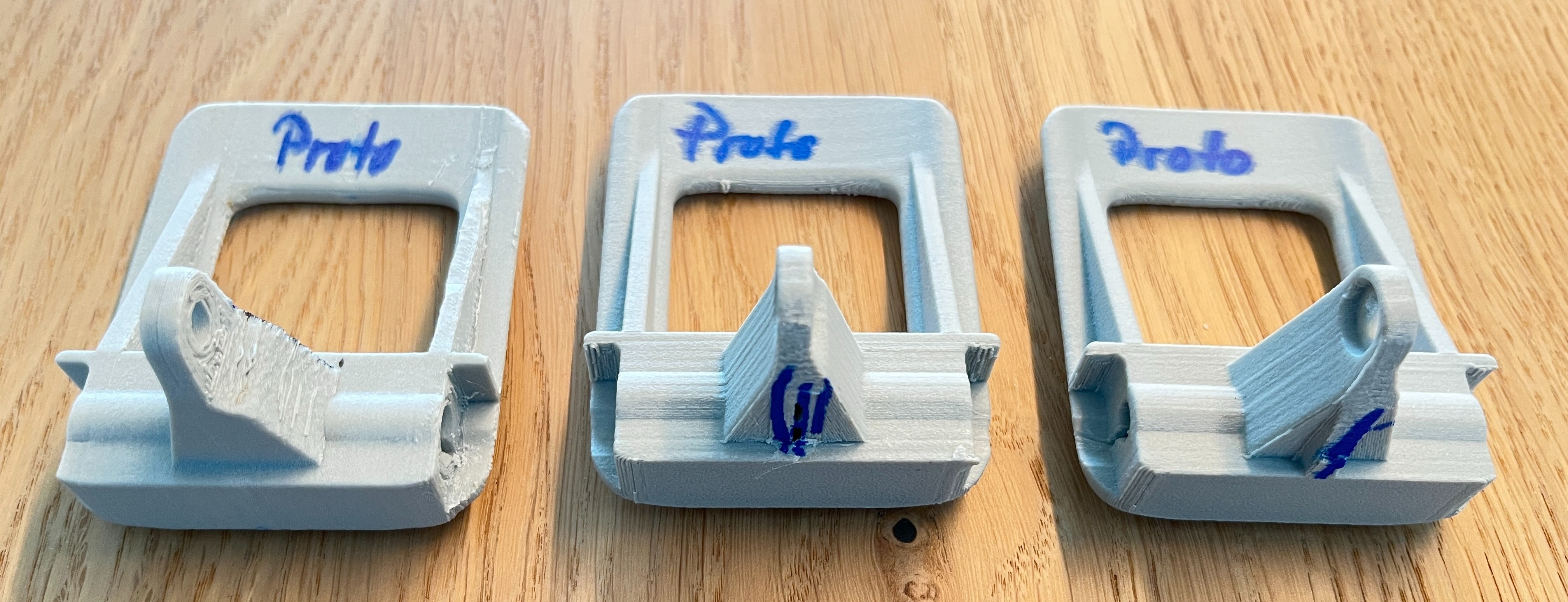

However, at this point we had already deviated from the original model in many places in order to incorporate reinforcements

However, at this point we had already deviated from the original model in many places in order to incorporate reinforcements  that would prevent further failure

that would prevent further failure

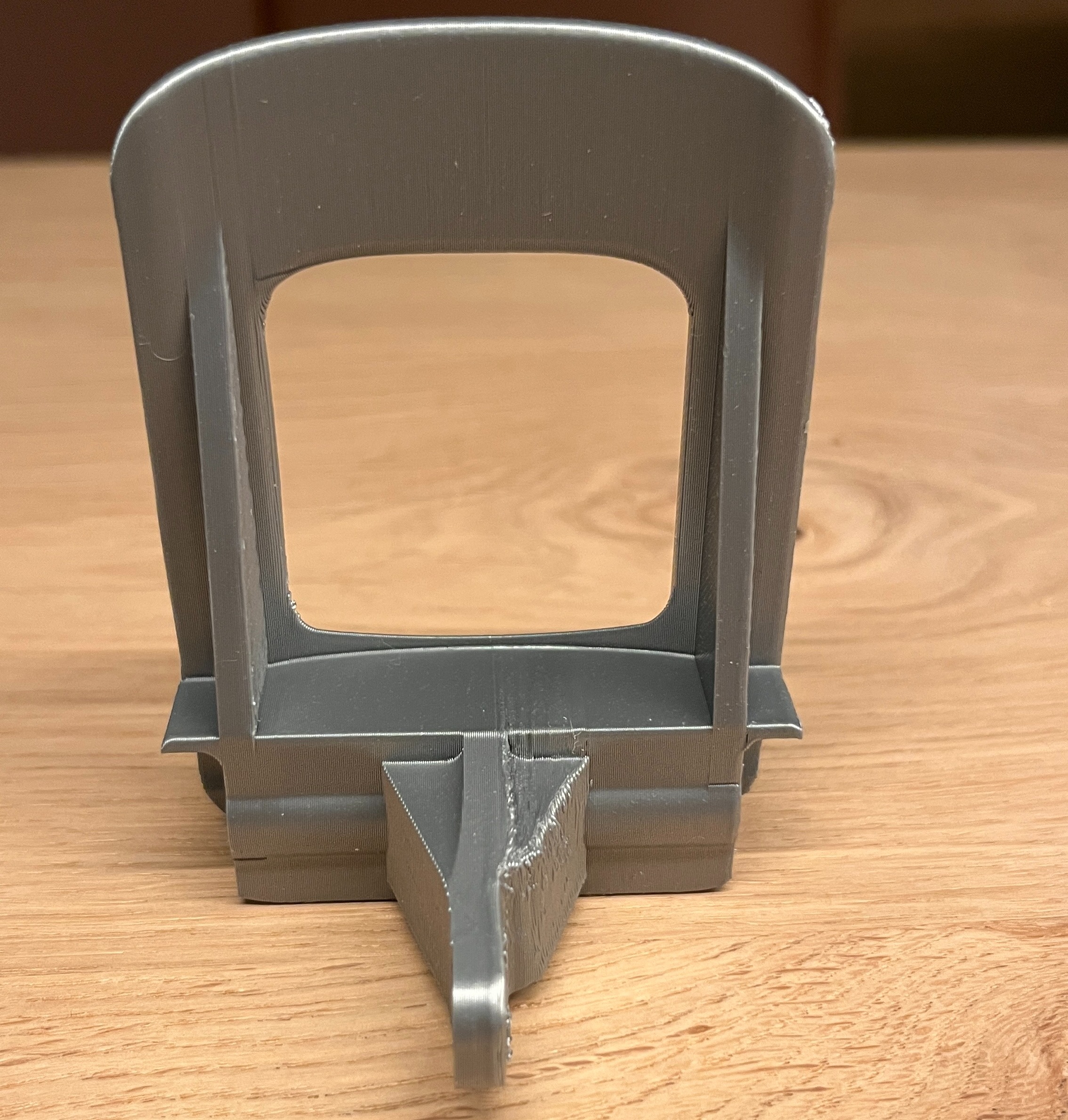

Despite the rather complex design, a first prototype was soon created and sent to the customer to be tested in the dismantled and unclad body door. This provided further insights into where the handle still rubbed when in motion, where our reinforcements were too thick, etc. Following this process, three further developed prototypes were produced until the customer was completely satisfied and the reinforced handle appeared to function properly. Now the item could be manufactured for the first time in the appropriate special material (glass fiber-reinforced ABS).

However, as there were also deviations in the accuracy of the printing with this material, two models were necessary here too before the final item could be created.

Since then, we have received further inquiries from motorhome owners of other brands who were similarly affected, where this handle was als installed and had now broken.

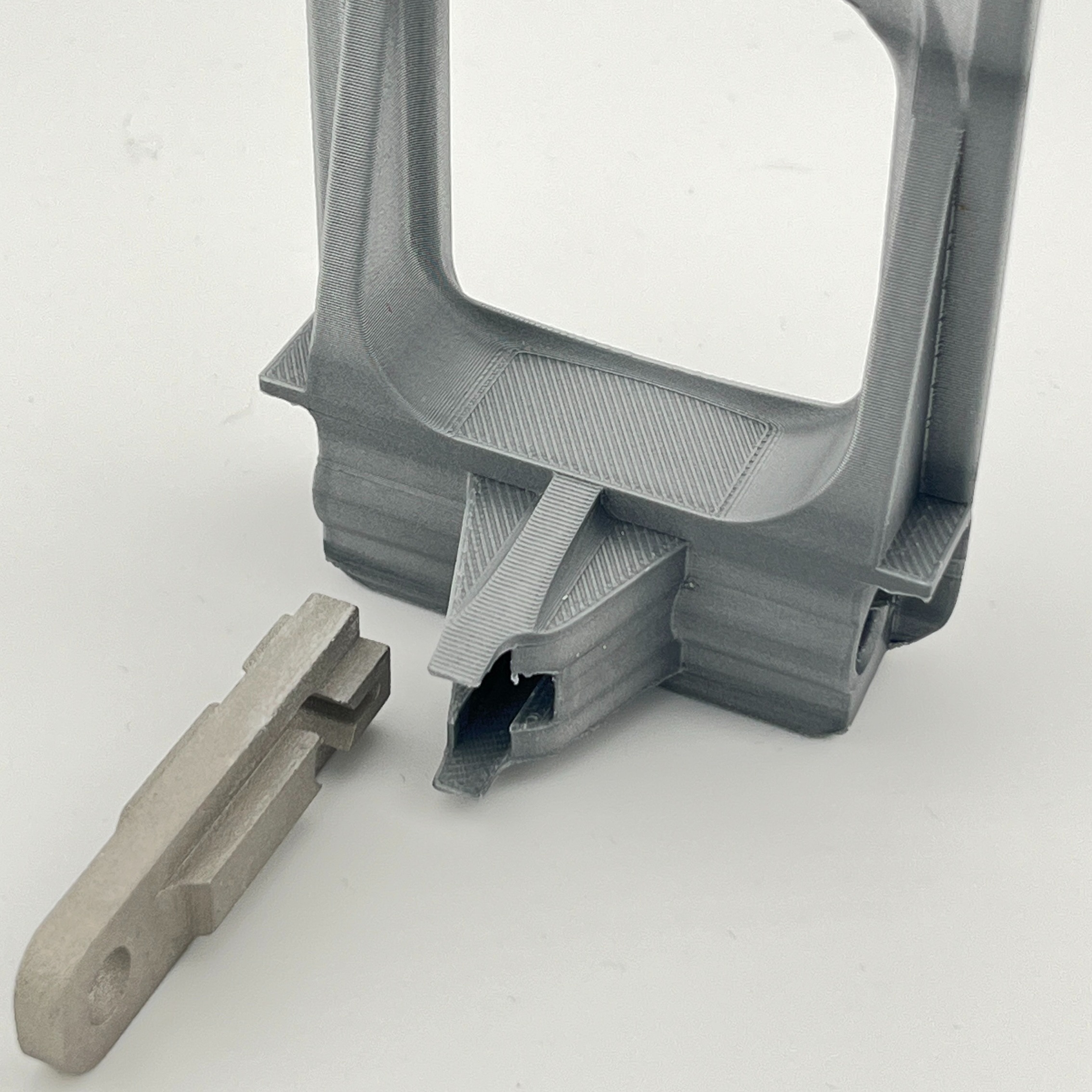

Based on the photos sent to us of the different mechanisms that the handle has to operate, we decided to further develop the current handle and consulted a metalworker.

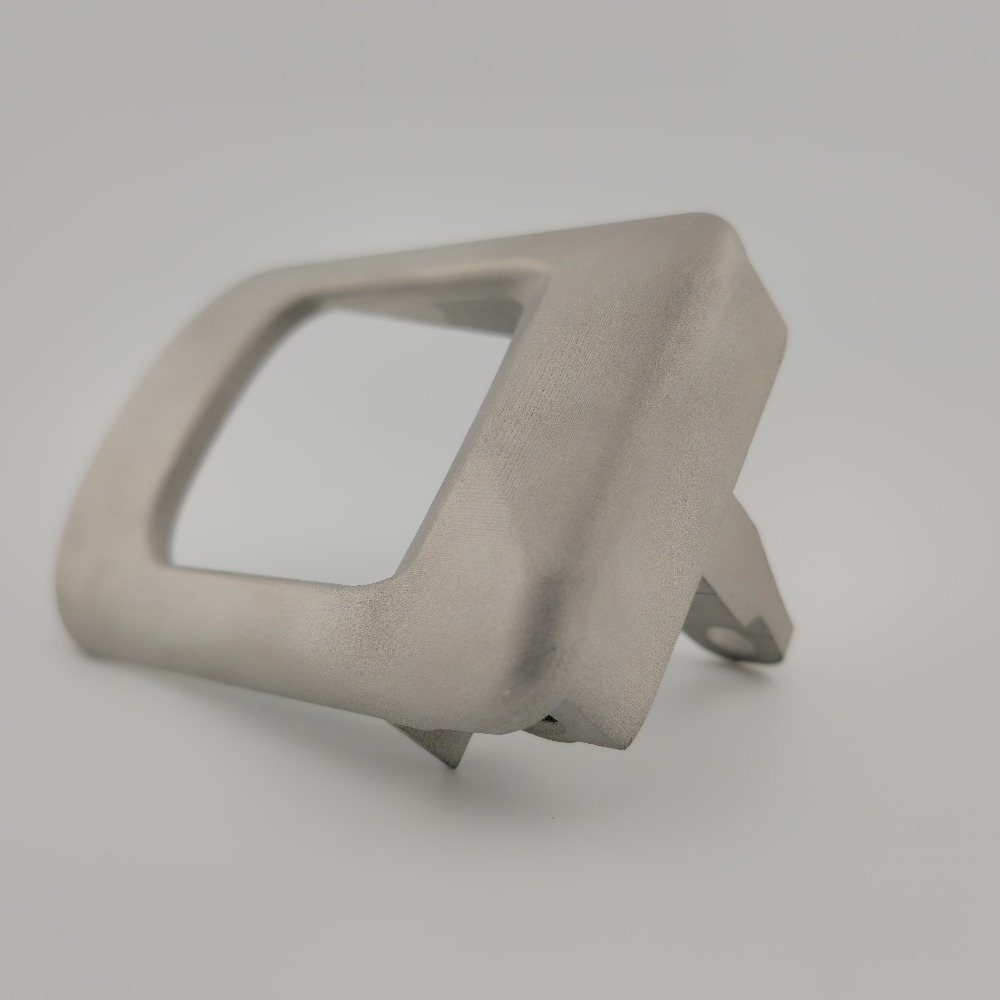

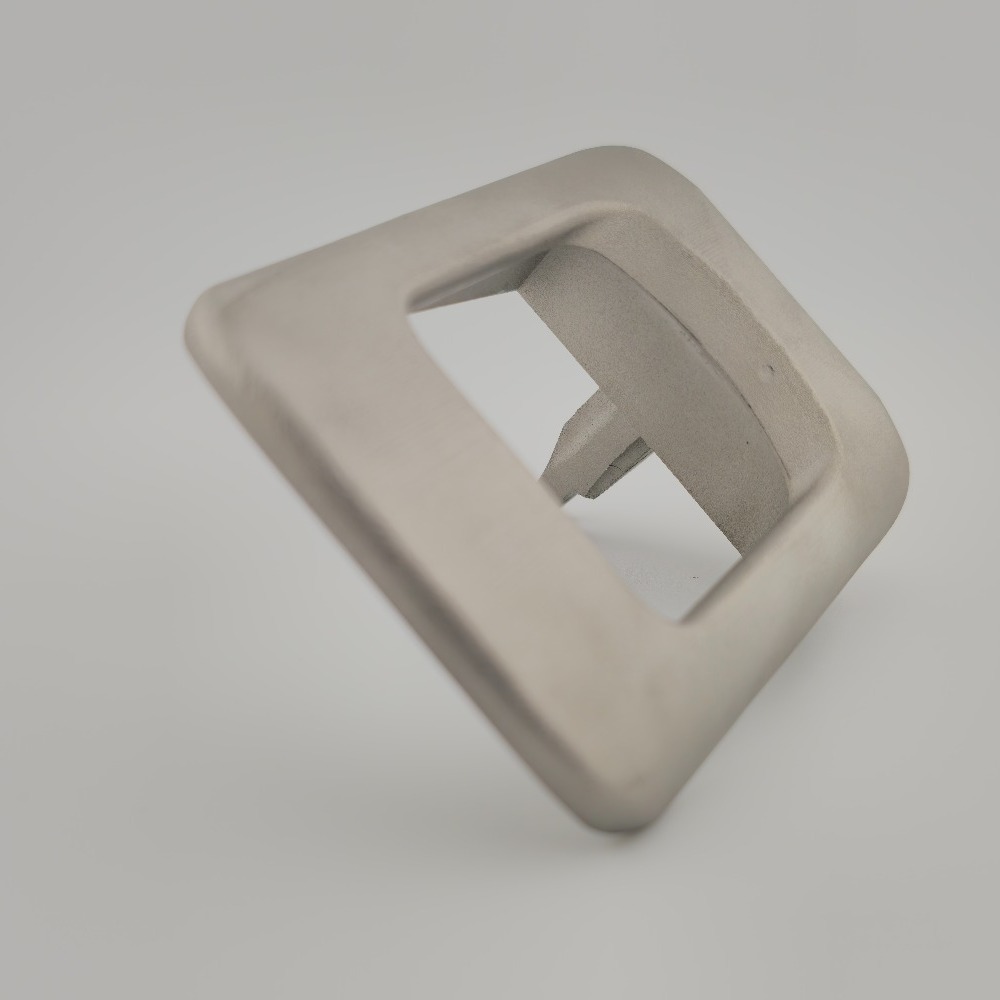

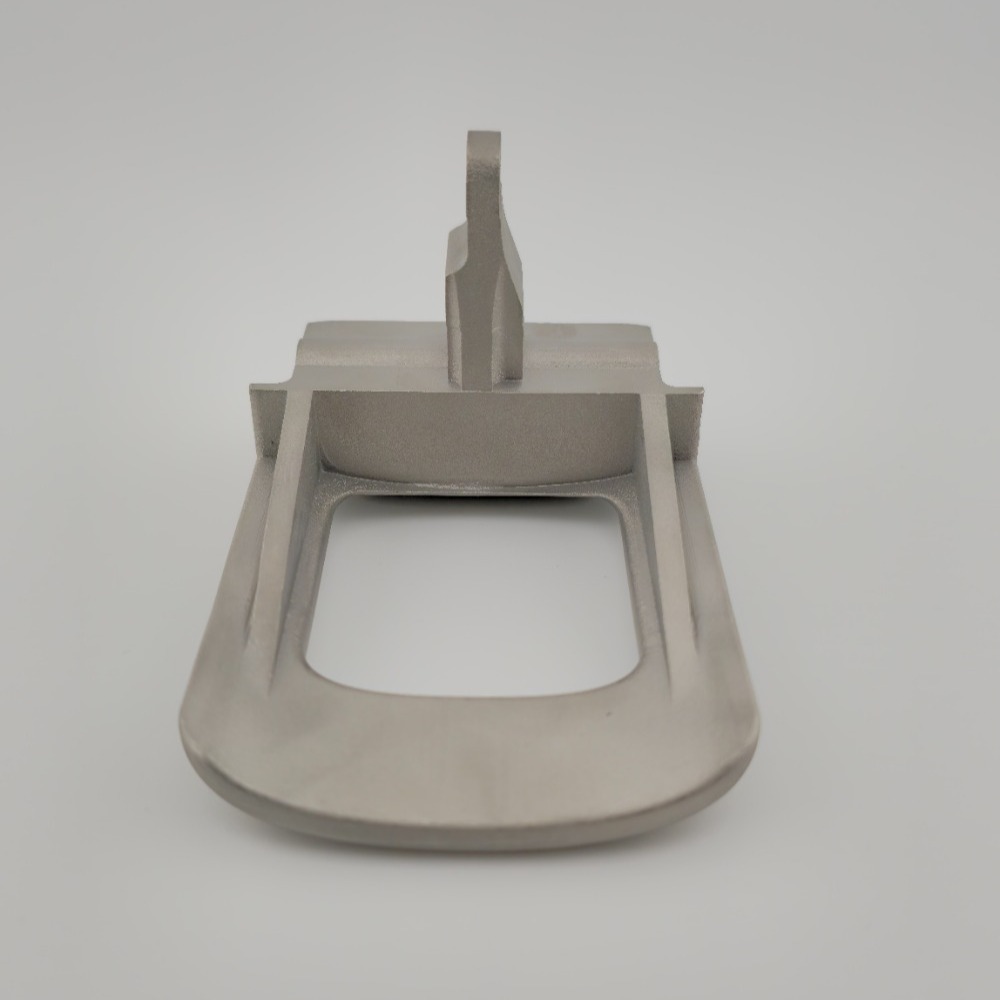

And as an ultimate solution: full stainless stell version of the handle, made by a third party metal coinstruction company.

Link to item in shop.